Local companies are at the forefront of a major Southern Water project to reduce the discharging of stormwater into the sea off the Island.

Wight Building Materials and Whippingham-based civil engineering company C45 are both key supply chain partners in the ongoing Southern Water scheme to greatly increase storage capacity at its wastewater treatment facility at Sandown.

Reducing number of discharges into the sea

By increasing the capacity of holding tanks, Southern Water can reduce the number of discharges into the sea when its systems become overwhelmed with storm water during heavy or prolonged rainfall.

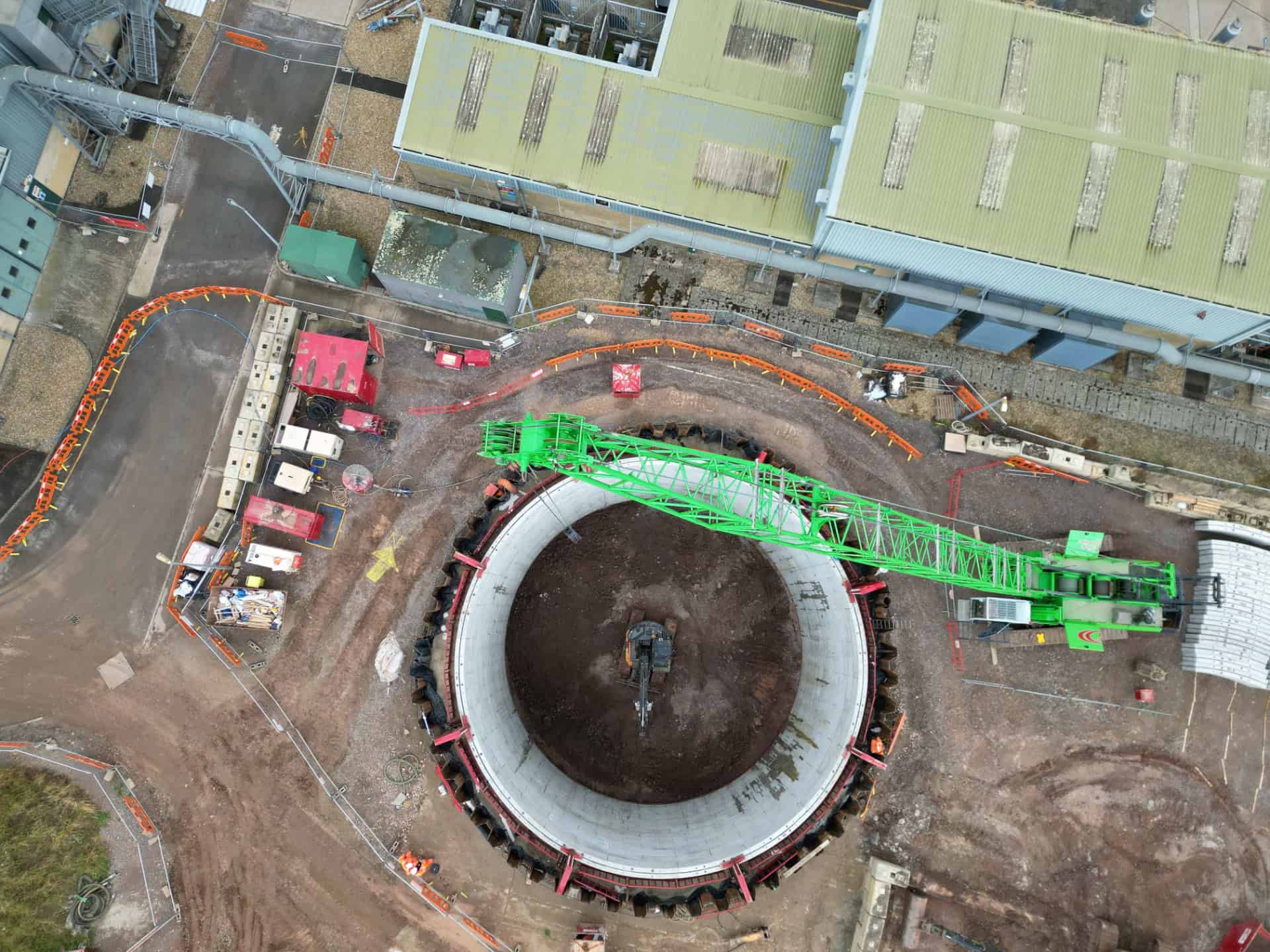

The project reached a key milestone this week as the concrete base was poured into a new 17-metre deep by 17.5-metre wide concrete storm tank. The new infrastructure, the largest of seven such storm tanks on site, can hold 4,000 cubic metres of water if required.

Concrete specially developed on the Island

The new base uses concrete specially developed at Wight Building Materials’ St George’s Down HQ to meet Southern Water’s stringent requirements to resist sulphate attack from the surrounding ground conditions.

It contains ground granulated blast-furnace slag (GGBS) which is a recycled by-product of the iron and steel-making industries and replaces 70% of the Portland cement normally used in concrete. GGBS is a sustainable, reduced carbon and durable alternative to cement and when combined with Island sourced aggregates minimises the overall carbon impact of this project.

In all 600 cubic metres, or 1,200 tonnes, of the specialist cement mix – which included Island sourced aggregate – was poured into the base by Wight Building Materials in three sessions over 30 hours.

Pitfield: Tried and tested local supply chain partners

John Pitfield, site manager with lead contractor Galliford Try, said,

“I am an Islander myself so it is great to be able to call on tried and tested local supply chain partners to play a role in delivering such an important local infrastructure project.”

Davies: Without locally sourced concrete, this project would not happen

Cameron Davies, project manager, of subcontractor Active Tunnelling added,

“The fact is that without locally sourced concrete, this project would not happen. It is the support and professionalism of companies like Wight Building Materials and C45 that makes large infrastructure projects such as this possible.”

Burton: Crucial for the Island to be able to source and supply local materials

Steve Burton, general manager of Wight Building Materials said,

“The project highlights how crucial it is for the Island to be able to source and supply local materials to the construction industry.

“We are delighted to be playing a part in supporting a project that is of such great importance to the local community.

“That we are able to do so is the result of our ability to meet the stringent specifications of major national customers by combining innovation with the ability to source local materials.”

News shared by Gavin on behalf of Wight Building Materials. Ed