Karen shares details of this latest innovation at Wightlink. Ed

Work will start shortly to install a sophisticated state-of-the-art mooring system at Wightlink’s car ferry terminals in Fishbourne and Portsmouth. This is part of the company’s £45million investment in a new hybrid battery ship for the route and improvements to port facilities.

Increase turnaround times

MoorMaster™ automated mooring units from technology company Cavotec will cut turnaround times on both sides of the Solent and improve timekeeping and efficiency.

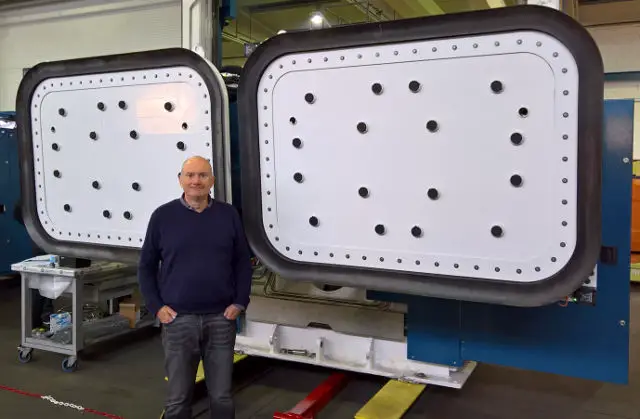

From summer 2017, remote-controlled vacuum pads fitted near the boarding ramps in Fishbourne and Portsmouth will connect with the hulls of Wightlink’s ships. They will hold the vessel securely in place while vehicles embark and disembark, without the need for additional mooring lines.

The ship’s Masters will initiate the MoorMaster™ system as the ferry nears the ports, then the pads will swiftly identify each ship and lock on to it within seconds.

A first for the UK

Although this is the first time the technology has been used for ferries in the UK, the tried and tested MoorMaster™ system is already in use by ferry lines, mining and shipping companies and ports around the world.

Project Director John Burrows, says,

“This is part of Wightlink’s major investment in future services. We estimate MoorMaster™ will cut our turnaround time by three minutes to 15 minutes which will help us improve our punctuality.”

Wightlink’s new environmentally friendly ship is now being built and will arrive in the Solent in summer 2018. Efficient double deck loading of the company’s current flagship St Clare will begin in summer 2017.