As reported during last week’s Scrutiny Committee, the Isle of Wight council have produced a set of FAQs in relation to the Cowes floating bridge.

Necessary due to the catalogue of delays and failures of Floating Bridge 6, the FAQs answer questions about the design, procurement and other operational issues. As they are embedded deep in the IWC Website as a PDF, we’ve reproduced the FAQs below for your convenience.

The IWC seem to have forgotten about their dedicated Floating Bridge Website which hasn’t had any news updated on it since January 2017, so don’t expect to find the FAQs there.

Frequently Asked Questions

Isle of Wight Council: Cowes Floating Bridge

(Version 1 – 14 June 2017)

1. Was the initial specification for the design of the new chain ferry the entire responsibility of the IWC or did the funders, the Solent LEP insist upon approving it before issue?

The initial specification was the responsibility of the IWC

2. Who ensured that the previous ferry operational and failure data was incorporated with in the body of the new specification?

This was collated by the naval architects for the project; Burness Corlett Three Quays (BCTQ) who met with Council officers and operational staff.

3. Who ensured that recent relevant studies, upon the operational performance of the old ferry, its associated chain system and two slipways were analysed and incorporated within the body of the new specification? (Southampton University 9 month study?)

This was analysed by BCTQ.

4. Was the selection of the design tenderers restricted to specifically qualified companies and who were they?

Due to the estimated value of the works the tender process for the naval architects was an open OJEU process in accordance with European Legislation; the tender was therefore advertised in the Official Journal of the European Union (OJEU) and included technical questions relating specifically to the suitability of the qualifications and experience of the bidding company for the services required.

5. Who subsequently undertook the technical analysis and cost assessment of the offered designs submitted by the tenderers and whose responsibility was it for the choice of the successful design tenderer (BCTQ)?

The Tender submissions were reviewed by the following:-

– Commercial Services Manager, Isle of Wight Coucil

– Fleet Manager, Isle of Wight Council

– Managing Director of the King Harry Steam Ferry Company Ltd (chain ferry) who was the Owners’ Representative for the project liaising between the naval architects, ship builders and the Council.The contract was awarded in accordance with the criteria set out in the tender documentation.

6. Who checked the development of the design into engineering manufacturing drawings by BCTQ?

Regular meetings were held between BCTQ, council officers and the owners’ representative to discuss the design.

7. Did the selection of the tenders for the construction of the ferry include local shipbuilders?

This was an open OJEU process, so the council was not able to restrict tenderers to a geographical location. Eleven companies initially requested the stage 1 documentation; out of this number there were two Isle of Wight based companies. Despite passing the stage 1 evaluation and being sent the stage 2 tender documentation neither company submitted a tender. Three tenders were submitted at Stage 2.

8. Did the assessment of the shipbuilding manufacturing tender submissions involve BCTQ and IWC

and SLEP?

The evaluation of the ship builders’ tenders was undertaken by BCTQ, IWC and Owners’ Representative.

9. Did pre contract discussions with the successful tenderer (Mainstay) include confirmation of physical shipbuilding, performance testing, acceptance for take-over, fixed price and stage payment basis with retentions and warranties and if so who undertook this confirmation?

Yes – this was undertaken by BCTQ, IWC and the Owners’ Representative. It included a visit to Mainstays’ yard to review all aspects of the contract. All of the items listed in the question were covered in the legal contract which was prepared by specialist marine based lawyers.

10. How were the separate contract arrangements for the modification of the slipways to meet the ferry design managed?

The design consultant for the slipways (PTR) liaised with the naval architects to ensure the requirements for the slipway were included in the technical works specification. This was overseen by the IWC. The slipway and associated works tender was let as an open tender which included technical questions relating specifically to the provision of the works required.

11. Was a separate contract for the supply of new chains let?

New chains have not been procured. The chain study undertaken by BCTQ showed that in normal operating conditions the life expectancy of a set of chains was 3 years. As the chains had only been replaced in November 2015 it was not considered necessary to replace them.

12. Who was responsible for the project management of the shipbuilding and slipway modifications and chains, plus assured that the three systems were compatible?

The compatibility issue was addressed at the design stage. Project management of the shipbuilding was undertaken by the Owners’ Representative and BCTQ through scheduled visits and meetings with PTR. The council’s commercial services manager supervised the slipway works with PTR.

13. Who was responsible for the performance testing, take-over certification and payments control for the entire project prior to it being offered to MCA for operational acceptance?

The shipyard are responsible for ensuring and demonstrating that the vessel is fit for purpose and meets the specification; this is being overseen by BCTQ on behalf of the IWC.

14. It is noted that the “Condition Report on the old Floating Bridge No 5” was produced by BCTQ on 23.09.2016, one year after they were awarded the contract to design the new Cowes Floating Bridge. It is also noted, however, that the crucial element, the hull, was assessed by BCTQ as “Good”. If so, why was a new Floating Bridge deemed necessary, when it had been more than self-funding, in fact in profit for years?

Whilst the hull was assessed as good, the vessel was 40 years old and approaching the end of its useful life; extensive works were required every year as part of the annual MCA inspection to ensure that it could retain its certificate and remain in operation. Accordingly the periods it was out of service and the associated costs were increasing year on year. This was detailed in the business case submitted to and approved by the LEP.

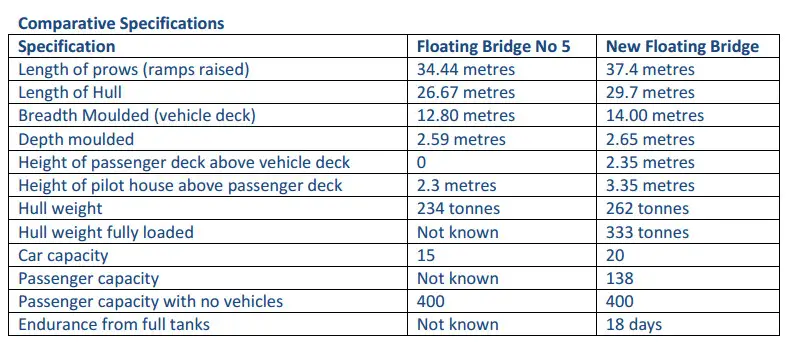

15. What are the specifications of the new floating bridge compared to the previous bridge?

Click on image to see larger version

16. How much does it cost the council to fund the concessionary fare for a return journey from East Cowes to Cowes?

The total cost to the council of a return concessionary fare between Cowes and East Cowes is £5.95. This is made up of 4 individual concessionary trips charged at £1.4868 per trip.

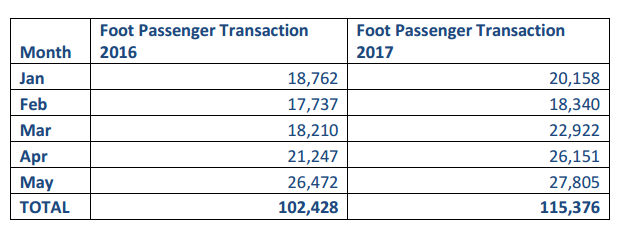

17. How many foot passenger ticket have been issued for the floating bridge from January May 2017 compared to the same period in 2016?

Click on image to see larger version

Image: © With kind permission of Allan Marsh